A Guide to Gasification – How Gasification Is Paving the Way for Sustainability

By Brad Price.

New Energy Risk helps accelerate the commercialization of industrial technologies that are solving global challenges. One of the technology platforms which we frequently review is gasification. This important process contributes to the production of low-carbon fuels and the development of a more circular economy, and we are proud to help our clients bring it to commercial scale.

What is Gasification?

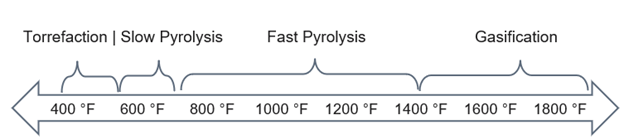

Gasification is a natural topic to follow my last blog post, A Primer on Pyrolysis, since it is the next step on the scale of thermal deconstruction chemical processes, shown in Figure 1.

Figure 1 – General temperature ranges of thermal deconstruction chemistries

Gasification is a process of partial oxidation (think partial combustion) that occurs above about 1400 °F (760 °C). It is used to convert a solid feedstock (like coal or biomass) or a liquid feedstock (like petroleum products), into synthesis gas (otherwise known as ‘syngas’). The key source of oxygen for the partial oxidation is usually either air, purified oxygen, or steam (via the “O” in H2O). The amount of oxygen supplied is significantly less than is required to completely burn the feedstock. Synthesis gas is primarily composed of carbon monoxide (CO), hydrogen (H2), and methane (CH4). ‘Synthesis’ (or ‘synthetic’) is in contrast to ‘natural’ gas, which is naturally occurring. Syngas and was historically produced from coal before petroleum-based natural gas was available.

Whereas pyrolysis results in a partial deconstruction of the feedstock, gasification can be considered a near-complete destruction of the feedstock into its most basic building blocks. It utilizes the brute force of intense heat and oxygen to break nearly all the chemical bonds in the feedstock; few other chemical processes operate at a higher temperature.

When fed with biomass feedstock, the gasification process can produce renewable, low-carbon fuels, chemicals, and various other products. Using biomass (like wood, grass, or other organic matter) as a fuel source is considered low-carbon and renewable because the carbon emitted during the combustion process is offset by the carbon that the plants absorb during their lifetime through photosynthesis. This carbon is normally returned to the atmosphere as CO2 during the natural decomposition process (i.e., rotting). This carbon is instead returned to the atmosphere when the gasification products are burned as fuel, doing useful work, and since the next generation of plants will absorb the same amount of carbon it creates a closed carbon cycle.

Another beneficial way to use gasification is when a waste stream is used as a feedstock, such as plastic waste, municipal solid waste (trash), or wastewater treatment sludge. Gasification can give new life to these materials. By using waste as a feedstock, gasification helps to reduce the amount of waste sent to landfills or incinerators, which can help to decrease greenhouse gas emissions and environmental pollution. Additionally, gasification can provide a local source of energy and reduce the reliance on fossil fuels, thereby contributing to energy security and promoting sustainable development. Overall, the use of waste in gasification allows for a more ‘circular’ economic system, where waste is repurposed and/or reused, rather than a straight-line path from production to disposal. This approach can help to reduce waste, conserve resources, and promote a more sustainable, circular economy.

Is Gasification New?

Far from it – gasification has a long history. As early as the 1820’s, the streetlights in England were fueled using synthesis gas (also known as “town gas”) from coal gasification plants. They were referred to as “coal distillation” plants and were operated to maximize the production of liquid tars; an important precursor to the burgeoning fabric dye industry (1). It is difficult to overstate the impact of this gaseous fuel byproduct of coal distillation on the day-to-day life of those who were able to access it because it was cleaner and more practical than other energy sources. Synthesis gas played a key role in the energy mix in the UK until the 1970’s, during which period 13 million homes were transitioned from synthesis gas to natural gas (2) This transition was a monumental undertaking that required the conversion or replacement of each and every town gas fueled appliance. It is fair to say that gasification and synthesis gas played a significant role in the industrial revolution.

Far from it – gasification has a long history. As early as the 1820’s, the streetlights in England were fueled using synthesis gas (also known as “town gas”) from coal gasification plants. They were referred to as “coal distillation” plants and were operated to maximize the production of liquid tars; an important precursor to the burgeoning fabric dye industry (1). It is difficult to overstate the impact of this gaseous fuel byproduct of coal distillation on the day-to-day life of those who were able to access it because it was cleaner and more practical than other energy sources. Synthesis gas played a key role in the energy mix in the UK until the 1970’s, during which period 13 million homes were transitioned from synthesis gas to natural gas (2) This transition was a monumental undertaking that required the conversion or replacement of each and every town gas fueled appliance. It is fair to say that gasification and synthesis gas played a significant role in the industrial revolution.

While gasification is not new, in many places it has been replaced by other more efficient fuel sources like natural gas. The story in the UK was repeated around the world as natural gas presented a much more energy dense alternative to synthesis gas as a fuel, and much less toxic due to the lower content of carbon monoxide. Despite this, it has never quite gone away.

A modern example of gasification is China’s chemicals industry. China has built an extensive chemicals and fuels industry on a foundation of coal gasification. While China is limited in its petroleum resources, its coal resources are vast. The National Energy Technology Laboratory (NETL) has documented over 100,000 ton/day of aggregate capacity for coal gasification in China, with over 70,000 ton/day capacity under construction (as of 2014). This capacity is used to produce base chemicals and products such as ammonia, methanol, synthetic natural gas, hydrogen, liquid fuels, DME, olefins, and plastics (3).

What Does Gasification Produce?

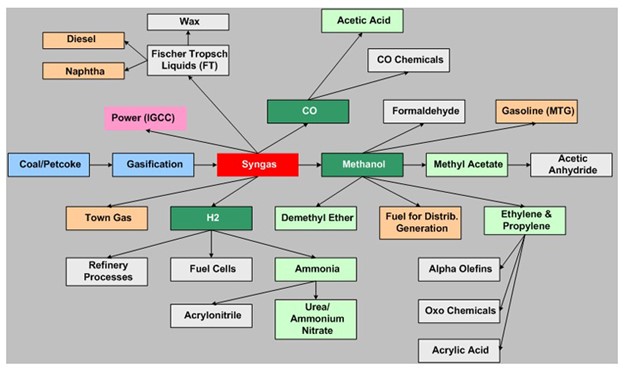

As mentioned earlier, gasification primarily produces a synthesis gas composed of carbon monoxide (CO), hydrogen (H2), and methane (CH4). Generally, however, this is not the final product or purpose of a gasification plant. The “magic” of syngas is the fact that it can be converted into so many different useful products.

Figure 2 below shows many of the different product pathways from a gasification plant. In addition to power, these include naphtha and diesel produced via Fischer-Tropsch Liquids, methanol, ethylene and propylene, hydrogen, ammonia, and many other products. As a result of these numerous pathways, gasification can be viewed as an alternative way of producing virtually every chemical that can be produced from petroleum-based feedstocks.

In addition to syngas, gasification produces small quantities of tars. “Tar” has a long history in the development of Organic Chemistry in the 1800s but has generally been poorly defined and is less important today. It is a mixture of high-viscosity aromatic compounds that can foul downstream equipment if not properly accounted for.

There can also be a carbon or coke product from gasification. This can be thought of as charcoal, although its properties can be somewhat different. The amount of coke produced depends greatly on the operating conditions and the feedstock composition.

Another undesirable byproduct of gasification is ash. Ashes are created due to contaminants in the feedstock that cannot be gasified, such as metallic and salt impurities. Depending on the operating temperature of the gasifier and the composition of the ash, this ash can melt or “slag.” Controlling the slagging conditions is important in all gasifiers.

Figure 2 – Chemical pathways from gasification (4)

What is New in the Story of Gasification?

Much like pyrolysis, recent innovation in gasification is related to feedstock. While coal has been industrially gasified for over 200 years, there are many feedstocks that had never been successfully gasified at scale until recently.

A perfect example of this is Fulcrum BioEnergy. Their Sierra BioFuels Plant gasifies municipal solid waste to produce syngas, which is then liquified using Fischer Tropsch technology to produce synthetic crude oil. Producing synthetic crude oil by gasification of municipal solid waste had never been done at scale before this facility. New Energy Risk partnered with Fulcrum Bioenergy in 2017 by providing a customized technology insurance solution to increase project attractiveness to investors (5). Fulcrum announced that in December 2022 the Sierra site had produced its first barrels of synthetic crude. (6)

In addition to municipal solid waste, many other feedstocks are being considered for gasification, including agricultural wastes and byproducts, wood, sewage sludge, and food production byproducts.

What Is the Business Case for Gasification Today?

Gasification is always an upgrading process, meaning it transforms lower priced feedstocks into higher value products. The products are generally commodity base chemicals or fuels. Since base chemicals all have the same product qualities, a competitive advantage cannot be obtained on the product side. As one might expect then, competitive advantage in gasification is related to the feedstock. Gasification’s business case is strongest when there is a financial advantage due to either a low-cost feedstock or a feedstock that is renewable or recycled, providing additional value to the products. Gasification represents a key pathway to low-carbon fuels and recycled materials.

Many of the business models New Energy Risk has seen are built around biomass as a feedstock for gasification. The material may be low-cost waste streams from other industrial or agricultural processes. The target products qualify for biofuel credits that then receive a Renewable Identification Number (RIN) and/or qualify for the Low Carbon Fuel Standard (LCFS) credits, which can be extremely lucrative, especially when used in transportation applications.

An advantage of gasification is that it tends to be able to handle feedstocks that are more contaminated (“dirtier”) and therefore less expensive to procure. This reiterates the importance of feedstock on the business model because a low-cost, contaminant-heavy feedstock is the ideal case for a successful gasification business model that can compete with other technologies.

Figure 3 – Gasifier types Source: Wikipedia

Another advantage is on the product side. As shown in Figure 2, gasification can be a precursor to many different chemical products. This flexibility tends to surpass any other chemical process. For example, pyrolysis only yields a crude-oil like product and requires further processing into higher-value products. This allows the gasification business model to be built around a low-cost or advantaged feedstock on the front end and pick from a wide range of products on the back end to maximize the total value created by the asset.

What Are the Challenges for Gasification?

Nothing is easy about innovation. To design a reliable (and profitable) process, technology developers must identify and mitigate many issues that are unique to each technology. Unfortunately, innovative technology projects frequently fail. Even with proper piloting, innovative process technologies on average only achieve ~80% of the design production rate six months after startup. Without proper piloting, this number is closer to 50%. (7)

The first challenge area for gasification is solids handling. Solids handling can be the bane of an innovator’s existence. While mundane, it oftentimes causes significant reliability issues. The feedstock and the coke and the ash byproducts are oftentimes sticky or otherwise difficult to convey and can cause mechanical problems due to buildup on the inside of the equipment. The equipment tends to require additional maintenance when compared with equipment in liquid or gas service. Spare equipment is oftentimes required to handle the outage time associated with these activities.

Tar formation represents a challenge to all gasification processes. When cooled, this material can polymerize and deposit on downstream equipment, resulting in significant plugging of equipment and downtime to clean it. Technologies exist that destroy these tars at extremely high temperatures, or chemically react them to more stable components. Every gasification plant needs to have a plan that has been field tested to handle these compounds.

Slagging is an issue for both slagging and non-slagging gasifiers. For slagging gasifiers, the ash needs to melt. This will require monitoring of the melting point and potentially adding material that ensures all the ash melts and ends up in the slag stream. These are some of the hottest gasifiers available, resulting in more technology risk because of these severe conditions. For non-slagging gasifiers, the ash needs to be monitored to ensure that it does not melt. For example, in a non-slagging fluidized bed gasifier, if the ash starts to melt, the entire fluidized bed can collapse, and then require a jackhammer to remove the agglomerated bed material from the gasifier. The feedstock is the primary determining factor of the ash melting point, so it is important for developers to fully understand the melting point of the ash in their feedstock.

How Can New Energy Risk Help with Your Gasification Process?

Financing an innovative gasification process can be a challenge, due to the risks associated with innovative technology. NER is positioned to provide performance insurance solutions to protect capital providers if the technology does not perform as expected. NER’s in-depth diligence process and innovative technoeconomic modeling allows us to quantify the risk associated with projects deploying these technologies. We have over a decade of experience enabling developers to de-risk their project and attract capital at terms that are impossible to achieve without insurance.

An example gasification client of ours is Fulcrum. NER was able to assist Fulcrum by helping to provide a performance insurance solution to protect bondholders in their project debt financing. In 2017, Fulcrum was able to secure $175 million in debt capital (bonds), and NER’s insurance product helped to improve the interest rate on those bonds by 2% annually. Construction at the site has completed, and the Fulcrum team announced in December 2022 that the site had begun production of their synthetic crude oil. (6)

Gasification is just one example of the innovative technologies that we evaluate and support at NER. This is part two in our series that takes a closer look at some of these innovations. Next up: A Teaser on Torrefaction.

Works Cited

[1] Aftalion, Fred. A History of the International Chemical Industry. Philadelphia : Chemical Heritage Foundation, 2001.

[2] Office for Budget Responsibility. Decarbonising domestic heating: lessons from teh switch to natural gas. [Online] July 2021. [Cited: March 13, 2023.] https://obr.uk/box/decarbonising-domestic-heating-lessons-from-the-switch-to-natural-gas/.

[3] Nathonal Energy Technology Laboratory. China Gasification Database. [Online] July 2014. [Cited: March 14, 2023.] https://netl.doe.gov/research/coal/energy-systems/gasification/gasification-plant-databases/china-gasification-database.

[4] Nathional Energy Technology Laboratory. 12.1. Overview: Chemicals From Gasification. [Online] [Cited: March 14, 2023.] https://netl.doe.gov/research/carbon-management/energy-systems/gasification/gasifipedia/chemicals.

[5] New Energy Risk. Case Studies. [Online] [Cited: March 14, 2023.] https://newenergyrisk.com/case-studies/.

[6] Fulcrum Bioenergy. Fulcrum Bioenergy Successfully Produces First Ever Low-Carbon Fuel from Landfill waste at its Sierra BioFuels Plant. News and Resources. [Online] December 20, 2022. [Cited: March 14, 2023.] https://www.fulcrum-bioenergy.com/news-resources/first-fuel-2-2.

[7] Andras Marton, Ph.D. Getting Off on the Right Foot – Innovative Projects. Independent Project Analysis Newsletter. March 2011, Vol. 3, 1.